Depending on our trial-and-mistake experiments it is highly recommended to cut reliable tissue samples into tiny (~ twenty mm3) pieces, Consequently greater drying area can be attained, which drastically will increase drying efficacy. Ensure that air can get to each bit of sample.

The freezing point of pure drinking water is 0 °C. Some other substances dissolved within the drinking water will reduce the freezing level. When inorganic salts are current, it may be significantly reduce. If a weak Remedy is frozen, pure ice will to begin with independent, thus rising the focus of the dissolved material within the residual solution (further decreasing the freezing point).

The biotechnology/biopharmaceutical sector has enormously grown which led into the creation of engineered antibodies for instance Antibody Drug Conjugates (ADCs), Bispecific T cell engager ( BITES), Dual Variable Domain ( DVD), Chimeric Antigen Receptor - Modified Tcells (CART) which are presently being used as therapeutic agents for immunology and oncology ailment problems. As well as other pharmaceuticals and biopharmaceuticals, all of these novel formats are fragile with respect to their steadiness/structure below processing problems which means marginal balance in the liquid condition and sometimes require lyophilization to improve their balance and shelf-daily life. This guide has chapters/subject areas which will explain every single facet of the lyophilization process and product or service advancement and manufacturing ranging from the overview of lyophilization process, gear expected, characterization of the material, design and progress with the formulation and lyophilization process, different procedures for characterization with the product or service, scale-up/tech-transfer and validation.

Protocols for lyophilization and their efficacy for numerous samples. Representative graphs and reference protocols with correct time, temperature, and strain values indicated for each section utilized for: a kidney, heart, liver, and lung tissue samples; b aorta and skin tissue samples; c peritoneal dialysis fluid focus; d liquid elimination from fecal samples.

In this article we aimed to deliver precise, detailed lyophilization protocols for animal tissues and other biological materials for laboratory exploration use and for scientific application too.

The biopharmaceutical industry is marked by groundbreaking products, which include Highly developed prescription drugs, therapeutic proteins, and vaccines. These products generally possess intricate buildings and so are vulnerable to degradation due to varied things like temperature, gentle, or the presence of h2o.

Lyophilization allows drug developers to stabilize formulations and therapeutic molecules through a commercially validated strategy. The process depends over the Charge of tension and temperature in a lyophilizer (Figure 1) to eliminate liquid from formulations that encompass thermally sensitive or hydrolytically unstable active pharmaceutical components (APIs) or formulation components.

To find out more in regards to the intricacies of lyophilization plus the part of strategic CDMO partnerships in optimizing the probable of the crucial process, enjoy our on-demand from customers webinar, Lyophilization excellence: Partnering for sterile fill end achievement.

In a very nutshell, the success of freeze-drying doesn't entirely lie during the equipment or the primary process. It is a holistic technique, looking at each individual moment depth, from understanding the nuances of temperatures and read more pressures to ensuring the tools and sealing processes are optimal.

Strain is lessened after which warmth is applied to flip the frozen h2o into vapor. Suppliers must be mindful to apply simply enough warmth to avoid melting and damaging the material [*].

By outsourcing lyophilization into a dependable and seasoned CDMO husband or wife, pharmaceutical businesses can concentrate additional on their core competencies, which include drug discovery and promoting, although leaving the complexities of drug producing lyophilization products for the CDMO.

What will be the strategic advantages of dealing with a agreement growth and production spouse (CDMO) associate which has substantial lyophilization knowledge?

I am able to revoke my consent Anytime with result for the longer term by sending an e-mail to unsubscribe@sartorius.com or by clicking about the "unsubscribe" website link in e-mails I've received.

Although there are actually a plethora of other traits and middleman phases which have to be analyzed and gauged all over the process, successful style and design of the a few phases above really should produce an acceptably lyophilized merchandise that may stand up to the stresses, pathways, and time to get towards the most crucial particular person inside the process – the individual.

Mackenzie Rosman Then & Now!

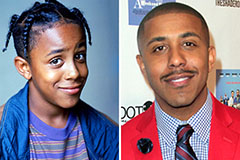

Mackenzie Rosman Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!